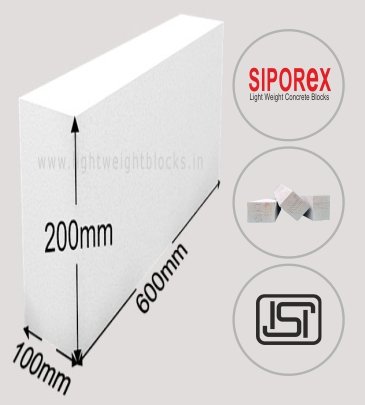

SIPOREX AAC BLOCKS

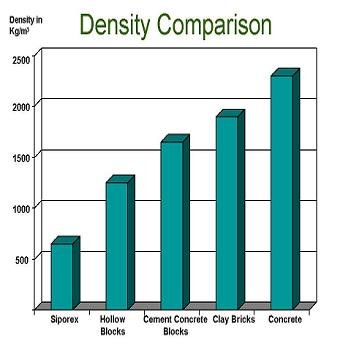

Siporex Autoclaved Aerated Concrete (AAC) blocks also known as Autoclaved Cellular Concrete(ACC) or Autoclaved Lightweight Concrete (ALC). It is a lightweight, precast building material that simultaneously provides structure, insulation, and fire and mold resistance.

AAC Blocks ( Autoclaved Aerated Concrete - " AAC ") a unique and excellent type of building materials due to its super heat, fire and sound resistance, AAC blocks is lightweight and offers ultimate workability, flexibility and durability.

AAC has excellent thermal insulation and acoustic absorption properties. AAC is fire and pest resistant, and is economically and environmentally superior to the more traditional structural building materials such as concrete, wood, brick and stone.